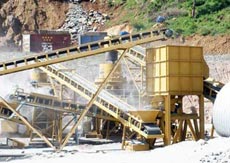

Dismounting Awareness of Jaw stone Crusher Parts

Basic Info

Model No.: TY-K164

Product Description

Jaw stone crusher is the most common used crusher of high efficiency, users should pay more attention to maintain and safeguard, sometimes repair when the jaw stone crusher is running

The necessary operation of jaw stone crusher is dismounting the critical parts Therefore correct installation and dismounting method is very important Liming Heavy Industry jaw stone crusher will provide some summarizes about this of our technical personnel according to customer’s feedback

For the jaw stone crusher, the most frequent repairing is changing the toggle plate And for the whole crusher with connecting rod’s removing of toggle plate, operation is under the steps: Firstly, screw out the bolt on duty Secondly, ct off the glycerol lubricating oil pope Thirdly, hang the toggle plate over the grab hook or other elevator equipment Lastly, loose the bearing, which is connected with the waling stripe, and pull the moving jaw to the direction of fixed jaw, then take out the toggle plate Notice (if the thrust board behind is also required to take out, the connecting rod, thrust board and moving jaw should be pulled together before taking out the thrust board behind) After the toggle board is taken out, lubricating oil pipe and cooling water pipe should be cut off immediately What’s more, the connecting rod should be put up by cartridge or strut, and then connecting rod cap can remove to hang out the connecting rod

The main axis of jaw stone crusher should be taken out with the belt pulley and flywheel Electric motor with pulley moves near to crusher along the slide runner to take down the triangle belt Then the axis should be hanged using crane When dismounting the moving jaw, the lubrication oil pipe must be cut off, and take off the cover of bearing, finally, the moving jaw can pulled out by crane or other elevator equipment

Contact us if you need more details on Elevator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lift、Dismounting Awareness of Jaw stone Crusher Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Iron Ore jaw Crusher

Premium Related Products