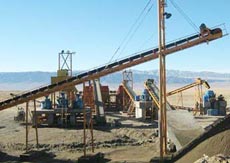

cement processing for cement plant in India

Basic Info

Model No.: TY-K164

Product Description

Cement manufacturing is one of the largest mineral commodity industries in India, with an estimated production capacity of greater than 73 million metric tons annually

Essentially the heart and soul of the cement manufacturing process, the kiln is a horizontal steel cylinder, lined with firebrick and sloped slightly downward, from the raw material feed to the fuel feed supply and burner pipe Typically, kilns will rotate at one to three revolutions per minute, heating the raw material mix to a redhot, 2,500plus degree molten form that emerges from the lower end of the kiln in the form of very hot, marblesized chunks known as “clinker” Once out of the kiln, the clinker goes through a cooling process When cool, the clinker is ready to pass through a series of grinding and milling processes that result in the gray powder we know as cement

The cement industry is very capital intensive Some of the major pieces of equipment include pulverizers, dust collectors, electrostatic precipitators, and rotary kilns

We are professional cement crushers, cement mills, cement publverizers supplier, and provide various cement processing machines Our products have successfully applied in customers worksite

Contact us if you need more details on Elevator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lift、cement processing for cement plant in India. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Rock Crushing Line

Premium Related Products