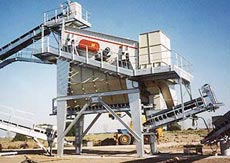

Mining activities crushing process

Basic Info

Model No.: TY-K164

Product Description

Mining is one of the oldest activities of man It is the se load the blasted rock and transport it to special, steeply lective extraction of ore from the Earth’s surface Man’s inclined ore paths The ore is then loaded into special mining activities began at the start of the Stone Age buckets and hoisted to the surfacealmost 25 Million years agoIf it is mineral bearing ore, it is transported to the Mining generally implies the physical extraction of ma processing plant If it is waste material extracted during terials from the Earth’s surface

Mining large volumes of the development of the mine, it is usually transported ore is often required to produce relatively small quanti directly to a refuse dumpties of the desired product or mineralGenerally, mining is used to obtain minerals or fuels A mineral can be defi ned as a substance of natural origin with a defi ned chemical composition with predictable and constant propertiesA mineral resource is a volume of the Earth’s surface with an abnormally elevated concentration of a mineral or fuel

It becomes a reserve if the ore and its content (eg a metal) can be recovered using current technology at a cost that allows a reasonable yield on the investment in the mine Before a mine is considered viable, the cost of production must be suffi ciently below Copper Chilean coins made in “Casa de Moneda,” the state coin maker the potential selling price of the mineral to produce acceptable returns on the sometimes huge investment

The next stage is crushing, milling and classifi cation of required the ore to reduce it to very fi ne particles, allowing the liberation of the sought after minerals The fi rst step in this process is tocrush the mineral into a suitable size using primary crushing equipment The ore is then passed into the milling and classifi cation process to reduce it to the fi ne particle size needed to allow the

desired mineral to be extracted

The milling process is carried out using very large revolving equipment referred to as grinding mills There are a number of different types of mills — including those which use steel rods or balls as the grinding medium within the mill These are referred to as rod mills or ball mills There are others which use just the force of the ore falling on itself to break it down into a smaller size These are known as Autogenous or AG mills Another common mill type uses a combination of both autogenous grinding and ball mill grinding—these mills are known as SemiAutogenous Grinding or SAG mills Water is added to the ore during the grinding process

This creates ‘slurry’, which is then used to transport the Typical copper ore found in Chilean copper mines ore throughout the remainder of the extraction process

In most hard rock mines, the ore is extracted by means SAG Mills constitute a recent innovation in terms of ore of drilling and blasting First, holes are made in the processing SAG Mills can currently be up to 110 m in ore body with hydraulic or compressed air driven diameter by 46 m wide and are considered more efdrilling machines Explosives are inserted in the holes fi cient than Ball Mills They can substantially reduce the and exploded causing the rock to fracture and allow crushing and milling process due to their large capacity extraction and effi ciency

In underground mines, special purpose machines with With SAG mills, the mineral is received directly from the diesel engine powered conveyors are often used to primary crusher (not from a secondary and/or tertiary

Contact us if you need more details on Elevator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lift、Mining activities crushing process. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : crushing process

Premium Related Products