Crushing Processing Plant Produces Materia in Netherlands

Basic Info

Model No.: TY-K164

Product Description

Customer: VAR Veluwse Afval Recycling BV

Wilp – Achterhoek

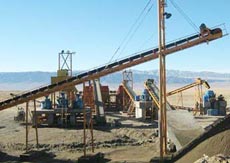

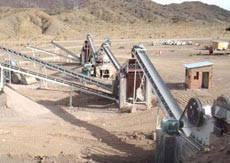

Crushing Processing Plant Desription

The processing plant comprises a crushing section with scalping screen and two screening and sifting sections to classify and separate foreign “light material” These processing steps beneficiate a high quality recycling product

The raw material is fed to the scalping screen by a specially designed apron feeder Case by case, the pre screened fraction 0/10 mm can be conveyed to stockpile or returned to the crushed product The oversize from the scalping screen is fed to the new generation Impact Crusher type APPH 1315/Q This crusher is a special design, characterised in particular by the hydraulically supported impact aprons, the rotor with its high moment of inertia and the easy blow bar changing system

The crusher discharge 0/40(x) mm is transported by vibrating feeder to a belt conveyor, at the end of which is an over belt magnet to separate the ferrous material The two screeningsifting units are arranged in series to clean the fractions >40 mm and 16/40 mm respectively from the light fraction such as paper, EXP, wood etc Then, the clean material can be conveyed either to the stockpile or back to the crusher The operation of the plant is very flexible which gives the opportunity to produce for any requirement the following products:

Products 0 – 16 mm, 16 – 40 mm, >40 mm

alternative: 0 – 16 mm, 16 – 40 mm, >40 mm in closed circuit

alternative: 0 – 16 mm, >16 mm in closed circuit

alternative: 0 – 40 mm, >40 mm

alternative: 0 – 40 mm, >40 mm in closed circuit

clean granulation 16 – 40 mm and > 40 mm

Technical Data Crusher Section

Feed material: demolition waste, reinforced concrete, broken road paving

Maximum size: 0 – 800 x 800 x 600 mm edge length

or slabs 2000 x 1000 x 500 mm edge length

Capacity: up to 350 t/h, depending on feed material

Pre screening: eccentric shaft screen; classifying 40 and 10 mm

Impact Crusher: APPH 1315 Q

Inlet: height: 1100 mm, width: 1520 mm

Installed power (crusher): 200 kW

Crusher product: 0 – 40 mm mit ca 4 – 8% oversize

Technische Data ScreeningSifting Section 1

Feed size: 0 – 40 (x) mm

Capacity: up to 350 t/h, depending on feed material

Screen: vibrating screen 1400 mm x 5000 mm

Sifter: drum Ø: 1000 mm x width = 1600 mm

Granulations: 0 – 40 mm, 40 – x mm, clean

Technische Daten ScreeningSifting Section 2

Feed size: 0 – 40 mm

Capacity: up to 320 t/h, depending on feed material

Screen: vibrating screen 2200 mm x 6000 mm

Sifter: drum Ø: 1000 mm x width = 2400 mm

Granulations: 0 – 16 mm, 16 – 40 mm, clean

Contact us if you need more details on Elevator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lift、Crushing Processing Plant Produces Materia in Netherlands. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Crushing Processing Plant

Premium Related Products