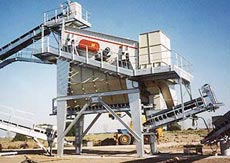

Largest Rubble Recycling Plant in the World

Basic Info

Model No.: TY-K164

Product Description

Plant Description

This plant, which has been erected inRotterdam’s port area, can handle concrete (with or without rebars), building rubble and broken asphalt paving at a rate of up to 1,000 tons per hour From a feed material of up to 15 metres edge length, a product of 80 % minus 45 mm is generated in a single pass

This performance is achieved by the world’s largest impact crusher, the APPH 2530 with a GSKtype rotor 25 metres in diameter and 3 metres in width and driven by an 800 kW slip ring motor Material feed is effected by two apron conveyors, the first of which extracts the raw material from the storage hopper with the second – fasterrunning – conveyor opening up the material flow to provide for the smooth and uniform feeding of an eccentric screen which separates the fines fraction

from the material flow prior to its entry into the impactor The crushed material is conveyed from the impactor by two vibro chutes installed in line At this point in the operation is a magnet separator for the removal of ferrous metal inclusions The plant was delivered complete with steel structures and electrical switchgear

Thanks to the size and rugged construction of the impactor, extremely low wear rate figures are anticipated, so that maintenance intervals and downtime for wear parts replacement are kept to a minimum Moreover, a number of maintenance aids are provided to minimise the time and effort expended for such operations

Technical Data For The Recycling Plant

Feed material: Building rubble, concrete (with or without rebars), broken asphalt paving

Feed size: 1,000 x 1,000 x 1,500 mm edge length – 5 %

0 – 600 x 800 x 1,100 mm edge length – 95 %

Capacity: up to 1,000 tons/hour according to feed material

Apron conveyor no 1: PBRK 2,550 mm wide, 20,000 mm C – C spacing

Apron conveyor no 2: PBRK 2,550 mm wide, 23,800 mm C – C spacing

Scalping: Eccentric screen 2,700 mm wide, 6,500 mm long

Separation at 45 mm

Impactor: Type APPH 2530

Inlet: height approx 2,000 mm x 3,000 mm wide

Total wt of impactor: 167,000 kgs

Wt of GSKtype rotor: 70,300 kgs

No of blow bars: 6

Wt of each blow bar: 1,550 kgs

Installed drive rating: 800 kW

Crusher discharge: 2 vibro chutes 2,600 mm wide x 5,000 mm long

Crusher product: approx 80 % minus 45 mm

Total installed power: approx 1,240 kW

Contact us if you need more details on Elevator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lift、Largest Rubble Recycling Plant in the World. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Rubble Recycling Plant

Premium Related Products