After Raymond processed Petroleum coke as a new energy

Basic Info

Model No.: TY-K164

Product Description

Petroleum coke is after crude oil by distillation to separate light and heavy oils, heavy oil and then by thermal cracking process, turned into a product From the exterior, the coke is irregular in shape, black block sizes (or particle), with a metallic sheen, coke particles with porous structure, the main elements of carbon, possession 80wt% Popular that petroleum coke is petroleum refining process is the most at the end of “waste”, if not through deep processing, its value will be very small, but after further processing a very wide range This article will look at how to become a petroleum coke is a new energy in the Liming Heavy Industry Raymond’s help

Now, after the shortage of petroleum resources on behalf of, petroleum coke by grinding mill processed into petroleum coke powder, replace oil as a fuel, it is to achieve waste utilization, the development of recycling economy, good material Petroleum coke powder substitute oil technology is currently in a good new energy discoveries and breakthroughs Petroleum coke processing into petroleum coke powder, can replace pulverized coal and oil as fuel Calorific value of petroleum coke is about 8300 ~ 8600kcal / kg, heavy oil calorific value 9500 ~ 10000kcal / kg, burning 11 to 12 tons of petroleum coke powder with 1 ton heavy oil calorific value considerably Petroleum coke powder heavy oil as a fuel substitute, in the case of heat is generated about the same, the use of petroleum coke powder as fuel costs far less than heavy, very substantial economic benefits

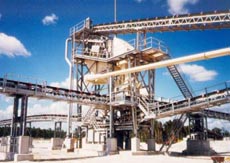

Petroleum coke after primary crushing by crusher, then by dryer for drying (some do not need drying), and finally by Liming Heavy Industry Raymond mill grinding, petroleum coke powder made in line with customer requirements, the quantitative continuous conveyor system, uniform and stable injected into the furnace for combustion

Raymond Mill widely used in the petroleum coke flour, petroleum coke flour is popular devices Liming Heavy Industry Raymond mill adopt advanced structure of similar products at home and abroad, and to update the industry on the basis of the improved design from Raymond, the device is higher than the ball mill efficiency, low power consumption, small footprint, disposable small investment Roller centrifugal force of the tightly compacted in the grinding ring, so when the roller, grinding ring wear to a certain thickness does not affect the yield and fineness of the finished product Roller, grinding ring replacement cycle is long, thus excluding the wearing parts centrifugal mill short replacement cycle defects The winnowing machine is circulating airflow job, so less dust than the highspeed centrifugal mill, operating plant clean, environmental pollution

Liming Heavy Industry provides a full range of petroleum coke processing equipment, including crushers, mills, conveyors, etc, onestop shopping, providing highquality products, while also allowing you to feel the caring service, we also provide production technology online configuration support, eliminating the aftersales trouble

Product Categories : Raymond processed

Premium Related Products