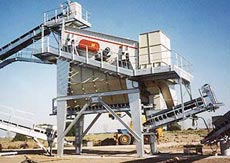

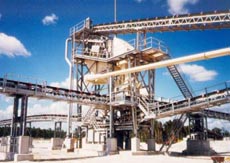

Stone materials processing production line

Basic Info

Model No.: TY-K164

Product Description

Liming research and develop stone materials production line equipments, to provide you with comprehensive technical support, the stone production line is mainly consisted of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, electric control and so on;

design production is generally 50500 tons / hour To meet the different processing needs of customers, can be equipped with cone crusher, removal dust equipment It can be used for hard limestone, granite, basalt, river pebbles, metallurgy slag and other materials’ aggregate and artificial sand operations It is used in hydroelectric, building materials, highways, urban construction and other industry applications Depending on the different process requirements, various types of equipment can be combined to meet customers’ different technical requirements

stone production line performance introduction

The stone production line has a high automation degree, except starting and closing equipment and routine maintenance, a set of production line almost doesn’t need manual operation It is of high efficiency, low operation cost, large output, high yielding, uniform finished stones size, good grain shape, meeting national highspeed material requirements

The equipment configuration of stone production line is mainly based on stone specifications, production and use of customer, we provide presale, sale and aftersale services, based on the customer production site to configure the process We strive to provide the most reasonable and economic lines for customers

stone production line basic process

Vibrating feeder sent large stone materials evenly to jaw crusher for coarse crushing, belt conveyor sent the materials after coarse crushing into the impact crusher for further crushing; belt conveyor sent the materials after fine crushing into vibrating screen for screening, screening out several different sizes of stone, belt conveyor sent the stone of meeting size requirements to finished product stockpiles; belt conveyor sent the stone of not meeting size requirements back to impact crusher for crushing again, to form a closed loop many times Finished product size can be combined and grading according to users’ need, it can be equipped with secondary dust removal equipment for protecting the environment

crushing equipments are matched reasonably, and have rigorous crossspace layout, so it has a small floor space, high investment cost, good quality aggregates, low powder output rate and other characteristics, and is equipped with advanced electronic control operating system, to ensure that the entire process can be smooth discharge, reliable operation, easy to operate, energy efficiency

Contact us if you need more details on Elevator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lift、Stone materials processing production line. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Rock Crushing Line

Premium Related Products